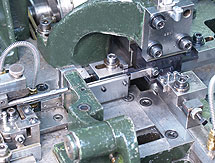

Atlantic Precision Spring’s vast number of diversified fourslide machines gives customers the guarantee that they are able to receive the finest quality parts and products at a better price than our competition. Our machines and equipment are constantly maintained and updated to keep up with tighter tolerance orders and to possess better control. A strong preventive maintenance program also adds to the success and reliability of the fourslide machines.

Fourslide Features and Benefits

3D Program

Atlantic Precision Spring uses a solid model “3D” program that is able to simulate the fourslide stamping in full production without even turning the machine on. This is another feature that sets us apart from competitors that are still designing fourslide stampings in “2D” software. Eliminating potential problems in the design stage will allow building time to be reduced, thus eliminating costly re-tooling of any fourslide tooling.

Process

Atlantic Precision Spring has perfected a process to build tools and manufacture parts inexpensively without losing quality. It requires much less tooling than progressive die sets and the stampings are able to be built in a fraction of the time. The fourslide machines are able to feed a strip of material into a small die set, which is able to perform simple forming and piercing operations. The strip then takes the shape of a progressive tool where it enters the cutoff of the fourslide machine.

Get Started

Start off by sending us an email with a picture and description of your part. Atlantic Precision Spring will quote your part with the lowest available price, the best delivery time possible; all while maintaining our commitment to precise quality.