Fourslide stamping or “multi-slide stamping” is designed to build tools and manufacture parts at an inexpensive cost without losing quality. We know this process inside and out and have perfected it throughout our 50 year history.

Fourslide requires less tooling than progressive die-sets and are also able to be built in a fraction of the time. We know potential and current customers are looking to receive parts with better quality at a less expensive price. We make that happen through fourslide tooling and stamping.

Flat springs from fourslide stamping

Our Fourslide Process

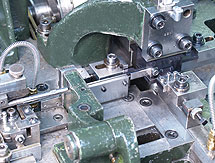

Fourslide machines are able to feed a strip of material into a small die-set, which is able to perform forming and piercing operations. The strip then takes the shape of a progressive tool where it enters the cut off of the fourslide machine. This is where the machine gets its name because just after the fourslide stamping is cut off, a tool slides in and starts the final forming of the material. Multiple slides are available to have tools attached and form the part into complex shapes.

What Sets Us Apart

Atlantic Precision Spring’s fourslide machines have been built with switches and sensors that aid in producing parts with tighter tolerances and better control. A strong preventative maintenance program also adds to our success and reliability. Work with us and we’ll tell you more about our fourslide options.

Fourslide Parts & Products

Atlantic Precision Spring’s fourslide stamping process enables us to make the metal parts and custom components that you need. Our fourslide machines are capable of manufacturing many products, including flat springs, small leaf springs, and electrical spring contacts.

Fourslide Stampings FAQs

What is fourslide stamping?

Fourslide stamping is comparatively an inexpensive alternative to other traditional ways. What makes this process stand out is as stated, it is an inexpensive alternative however you do not lose quality; it is still designed to build tools and manufacture parts with the same quality, just inexpensive in comparison to other ways.

What is the multi-slide stamping process?

Like the name, there are multiple slides available during the process. Multiple slides are there to have tools attached to and form the part into complex shapes. Before this happens, the machines are fed a strip of material and transformed into a small die-set, done by the machine performing forming and piercing operations. The strip takes the shape of a progressive tool where it enters the cut-off of the fourslide machine.

What is different about Atlantic Precision Spring’s fourslide stamping process?

At Atlantic Precision Spring we use a solid “3D” model program that is able to simulate the fourslide stamping in full production without actually turning on the machine. This results in better products, faster turnaround time, and lower prices.