Batteries convert stored energy into kinetic, or active, energy. That energy is forwarded to the device where the battery is located. To make this happen, the battery must somehow be connected to the device. That’s where beryllium copper springs come in. These units help make the battery function, and the material makeup boasts a number of benefits over other spring types.

Main Functions

Prior to even thinking about transporting energy from a battery to a device, a contact’s first task is to physically hold the battery in place. A battery is potentially hazardous if it cannot maintain a consistent position to conduct electricity, therefore rendering the connected device useless. Beryllium copper springs act as that needed liaison by providing a stable and sturdy resting place.

The functionality of energy flow relies on three components. It poses these questions:

- Can beryllium copper contacts conduct electricity?

- How safe is the product?

- What’s the overall performance like?

Conductive Capability

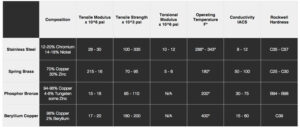

The connecting spring, also known as a contact, must have conductive properties in order to transport energy from the battery to the device. Many different materials are conductive, such as copper, aluminum, gold, silver, etc. When it comes to metals, none has a higher electrical conductivity than copper.

Most material that is purchased for beryllium copper contacts is UNS C17200 which is certified to 97.9% copper (Cu), 1.9% Beryllium (Be), .02% Cobalt (Co). The full physical properties are density .302 lb./ cu in., elastic modulus 106 psi = 19, thermal expansion coefficient / 700 F to 4000 F = 9.7 x 10-6, thermal conductivity Btu/(ft-hr-0 F) = 60, and melting temp. 0F = 1600-1800.

Safety Concerns

Advantages of Beryllium Copper Springs

A battery needs a safe conductor due to its makeup. It needs a conductor that can withstand corrosion caused by acidic properties and frequent wear and tear, and deterioration by the elements.

Beryllium copper springs do just that. These contacts are resistant to the non-oxidizing acids found in batteries. They are also very elastic – able to bend, twist and turn when needed. The resulting flexibility prevents disfiguration from recurring usage, giving beryllium springs a much-needed durability aspect.

Additional safety features are that they are nonmagnetic and do not spark. Even a minuscule magnetic pull one way or the other could drastically change the performance of any specific device. Sparking could obviously lead to a far more significant issue such as a fire or an electric shock. The safety perks alone help justify this material above others when being used in certain contact applications.

Performance

A battery contact must have a high performance level. High powered machinery, medical instruments, electronics and more all rely on how well a battery operates. Failure could result in downtime and terrible financial loss.

Designers of electrical contacts also have to be aware of the current that is expended during the opening and closing of a circuit. This is due to the initial completion and opening of the circuit. Some loss is inevitable but can be reduced by making sure beryllium copper is used with the best finish applied.

Drawing from the durable design, beryllium contacts boast longevity and are able to perform for substantial periods of time. More importantly, beryllium copper springs offer the strongest force out of any copper-based alloy. They yield comparable strength to that of carbon steel, yet at a fraction of the thickness.

They can also withstand intense high temperatures and still conduct effectively. This results in beryllium copper contacts being used for a wide variety of batteries throughout an even broader range of devices. This is also possible thanks to the contacts being highly customizable. Since beryllium copper can withstand high temperatures, the springs can be molded in the design phase to any specification. Beryllium copper springs can be specially made in size and shape depending on the function needed. And Atlantic Precision Spring takes any type of custom order.

Not only do these contacts possess the capabilities necessary for a high functioning battery unit or system, but also rate extremely high when it comes to safety and performance. The summary ends up making these springs the perfect choice!