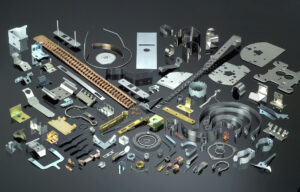

Spring Clip Fasteners

Ranging in size from .003 inches to .125 inches thick, Atlantic Precision Springs’ spring clip fasteners and industrial clips are typically made from materials such as carbon steel and stainless steel. These materials are available in all grades and tempers, allowing you to customize your product to fit any specific requirements.

We offer a variety of types of spring clips and fasteners, each designed for optimal performance in various applications. The manufacturing processes at Atlantic Precision Spring are unique and what ultimately sets us apart from the competition. The use of annealed material is vital in order for high carbon steel to undergo complex forming. The material is then heat-treated and tempered to obtain its full spring characteristics. Stainless steel is the most common choice due to its resistance to corrosion. With our finishing capabilities, zinc or nickel plate finishes can be applied when the final product calls for rust prevention.

The production method is dependent on these characteristics of the part:

- Material type

- Material thickness

- Overall size

- Volume

- Complexity

Learn more about other production methods below:

Tooling

We can create tooling for a wide assortment of power presses that range in size, tonnage, and speed. This is best for large volume precision spring clips fasteners.

Fourslide

Also known as a multi-slide machine, this process produces the parts at a fraction of the cost of a power press progressive tool.

Short Run Metal Stamping Department

Our short-run metal stamping department is equipped with pneumatic presses that can bend, cut, and draw, customer prototypes are built with a minimal amount of tooling required. Great for smaller quantities or trials.

Metal Stamping Applications

Atlantic Precision Spring is a leader in the manufacturing of spring clip fasteners. We produce a wide variety of clip fasteners for many different applications, including automotive, aerospace, medical, and hardware.

Our quality assurance department adheres to the policies and procedures of ISO 9001:2015 certification. Our dedicated team closely manages and monitors projects from start to finish, allowing you to get the best manufacturable part with minimal design sacrifices.

What Are Spring Clip Fasteners?

Spring clip fasteners are one-piece fasteners that are placed into a mounting hole, rim, or panel edge trim. A cylindrical object is placed into the fastener through spring tension. Other fasteners such as screws, studs, and rivets are not needed because the spring tension securely holds the clips in place. APS can form various sizes and shapes of spring clip fasteners for various industries.

What Types Of Fasteners Are Used With Sheet Metal?

There are a variety of fasteners that can be used with sheet metal such as studs, weld studs, rivet nuts, and threaded fasteners. These self-clinching fasteners provide exceptional torque resistance for adequate fastening to sheet metal. With over 50 years of experience, Atlantic Precision Spring can create the exact spring fasteners that your product needs.

What Are Spring Clip Fasteners Made Of?

Spring clip fasteners are generally made with steel and carbon. At Atlantic Precision Springs, we allow you to determine the specific grade and temper to meet your project’s needs.

What Industries Use Spring Clip Fasteners?

There is a large variety of industries that use fasteners, such as medical, automotive, aerospace, hardware, telecommunications, electrical engineering, and construction. Spring clip fasteners have a variety of different functions and are used in everyday items.

What Are The Different Types Of Spring Clips?

Transistor clips or gull-wing clips, r-clips, linchpins, spring hose clamps, terry clips, s- clips, circular spring clips, spring button clips, command spring clips, circular metal clips, and u-clips (which we manufacture a lot of) are all types of spring clips. Get a quote for your spring clip specifications.