If there is one thing that is guaranteed in your life, it is that you will interact with countless people and objects in your life. Yet, when you really think about those interactions you’ve had, you can probably begin to categorize them into different groups. You’ve been to the doctor before, but there are subsets of that category: physician, dentist, ophthalmologist, or maybe even a surgeon. You can say the same about your cars- sedan, SUV, suburban, or truck. You can even delve into those subcategories more- Tacoma, F-150, 3500 are all styles of trucks. When you really think about it, every interaction you have is with a person or object that can be grouped into a larger classification, and that classification can probably be grouped as well. That is a cycle that can continue to repeat and applies to custom metal stamping as well.

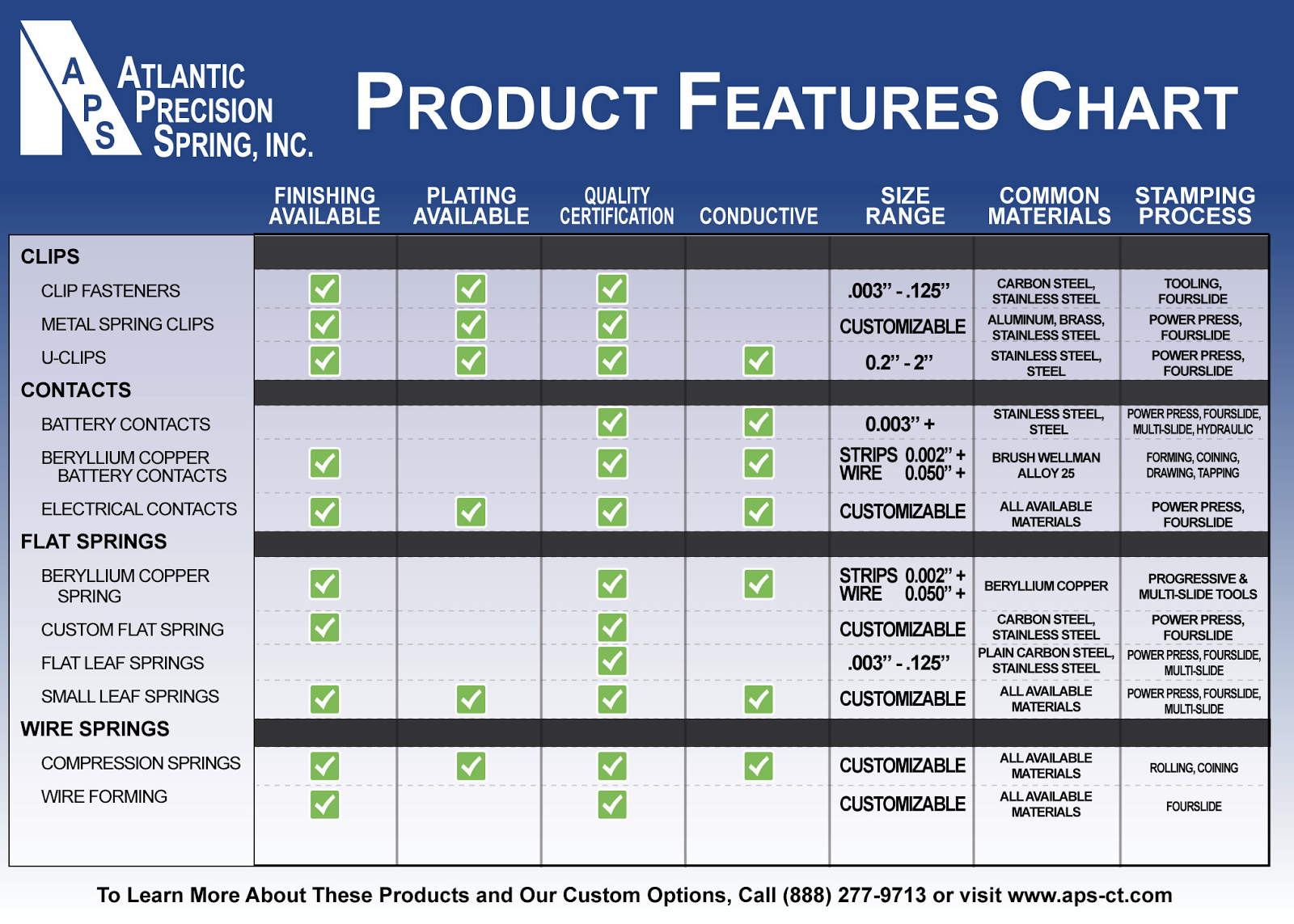

Metal stamping in itself can be broken down into multiple products- such as Clips, Contacts, Flat Springs, or Wire Springs. Then, from those products, you can even dig deeper into each category to see even more available products. Curious about the similarities and differences between these various categories of metal stamping products and their capabilities? View the chart below.

Metal Clips

Metal clips are a crucial piece across many different industries and applications. During the assembly process, when screwing is not an option, metal clips are the best options for securing pieces. However, depending on the application, there are multiple options and styles of metal clips, including the following:

- Clip Fasteners – Clip fasteners are a complexly formed piece that are heat-treated to obtain full spring characteristics. Plating is also applied after production to help with rust prevention.

- Metal Spring Clips – Completely customizable and intended to fit even the most specific of needs, metal spring clips can be made of any number of available materials.

- U-Clips – Made from a bendable alloy, uni clips (which are also referred to as U-Clips) are widely used across many industries, including aerospace, medical, and electronics.

Contacts

When it comes to metal contacts, the purpose is simple, be an assistant to electrical devices such as remotes, phones, games, tools, and other machines. However, with uses in military, appliance, hardware, aerospace, and automotive fields, there are different requirements and specifications needed from these contacts. This is what creates the additional styles of contacts, such as:

- Beryllium Copper Battery Contacts – These battery contacts are an industry leader due to their formability, elastic properties, and electrical conductivity they get from the use of Beryllium Copper, or BECU.

- Electrical Contacts – The parts that make up crucial electrical devices like switches, breakers, or relays- electrical contacts have a wide range of possibilities. They can be made out of almost every available material, which all comes down to a dependence on the voltage they’re acting as a contact for.

Flat Spring

When talking about flat springs, it is no surprise that some can be produced at a thickness smaller than 0.003”, which is about the thickness of a piece of paper. Even with a thickness so fine, flat springs can be custom stamped up to 12” on some projects depending on the intricacy of design. Some of the most common types of flat springs available include:

- Beryllium Copper Spring – Similar to their usage with battery contacts, Beryllium Copper, or BECU, can be a great material for spring production. This is due mostly to the great strength beryllium copper has after production.

- Flat Leaf Spring – A leader in naval and automotive industries, flat leaf springs are a piece that attracts much interest, both on a small scale and large scale of ordering. Versatility in production equipment on the part of a manufacturer is a great testament this product’s popularity.

- Custom Flat Springs – Since flat springs can be used by so many companies in so many industries, there are a lot of options available. When the well-known, mass-produced products don’t fit into a person’s needs, that’s when it’s time to have a custom flat spring produced to the size and materials they need!

Wire Spring

When looking at the wire coils being utilized by engines (both large and small), medical instruments, and mobile devices, you are likely looking at wire springs. These are open-coil helical springs and have the ability to resist force compressively that is applied on an axis. The usual types of wire spring production you see are:

When looking at the wire coils being utilized by engines (both large and small), medical instruments, and mobile devices, you are likely looking at wire springs. These are open-coil helical springs and have the ability to resist force compressively that is applied on an axis. The usual types of wire spring production you see are:

- Compression Springs – Compression springs are produced with one of the following shapes- cylindrical, conical, barrel, or hourglass.

- Wire Forming – Wire forming follows a process, just as the name states, of forming coils and wires to

your determined shape and specifications. The image to the right shows an example of some wire forming options.

your determined shape and specifications. The image to the right shows an example of some wire forming options.

So, as you can see, while you may know about a certain metal stamping product, there may be additional subcategories of that product. So there always seems to be something to fit a person’s need depending on what their project is. Next time you see a custom metal spring, clip, or contact, see if you can tell which specific product you’re looking at or what it’s parent category might be.